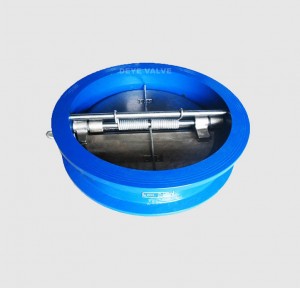

Double Disc Check Valve

Quick Detail

Design standard: API594

Body material: ductile iron

Disc: SS304

Seat: EPDM

Nominal diameter: 8″

Pressure: 150LBS PN20

End connection: Wafer to connect flange ANSI B16.5

Face to face: ANSI

Working temperature: -40℃~+125℃.

Test and inspection: API 598.

Double disc spring loaded Check Valve

Epoxy powder coated inside and outside Min. 250Microns.

Available Body Material: Cast Iron GG25, Ductile iron GGG40, GGG50

Available Disc Material: Ductile iron, Bronze, SS304 SS316

Optional Seat Ring: EPDM, NBR, PTFE, VITON

Optional Ends: BS4504/EN1092-1 PN16/ ANSI B16.5 RF

Size Range: DN50-DN800 (2″-32″)

Pressure Range: PN10, PN16, PN20(150LBS)

Optional surface color: RAL5002, RAL5015. RAL5005, red, black. Or customized

• The innovative Dual-Plate Design employs two spring-loaded plates suspended on a central vertical hinge

• As Flow Begins, the plates open in response to a resultant force Which acts at the center of the sealed Surface Area

• The Contact point of the reacting spring leg’s force acts beyond the center of the plate area, causing the heel to pen first. This prevents rubbing of the seal surface prior to normal plate opening

• As the velocity of flow decreases, torsion spring action reacts automatically. The moves of plates closer to the body seats, reducing the distance and time of travel for closure. By Having the plates closer to the body seats at the time of flow reversal. The valve dynamic response is greatly enhanced, This dramatically reduces the water hammer effect

• At closing, the point of spring force causes the plates to close first. This prevents dragging of the heels of the plates and periods maintains seal integrity for much longer Periods

Steam, Superheated Water, Hot Water, Cold Water, Fluids without acidity or alkalinity properties, Chemicals