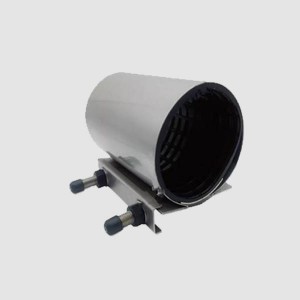

GRIP EPDM Repair Coupling

Feature

1. Flexible connectionFirmness and rot- resistance

2. Need no welding

3. Without fire danger

4. Saving space

5. No limit on a pipe

6. Non-stop plugging

7. Convenient installation.

Install Tips

1. Clean up the appearance of the pipe as thoroughly as possible.

2. Make a reference mark on the pipe. After the installation is complete, this mark can be used to check whether the patcher is accurately covered.

3. Use water, soapy water to lubricate the pipe, reduce friction and make the seal easier to install.

4. Clean and lubricate the bolts will reduce the friction so that the torque can be transmitted to the lock more easily.

5. Maintain a certain pressure in the pipeline so that the water will continue to flow and prevent foreign matter or pollutants from entering the pipeline.

6. The full-circle patcher can be easily installed to the damaged part and installed easily when the piping is fully lubricated.

7. Raising the water level above the pipeline will reduce the water spray. Patcher can be installed quickly and easily in water.

8. First tighten the middle bolt to prevent water spray.

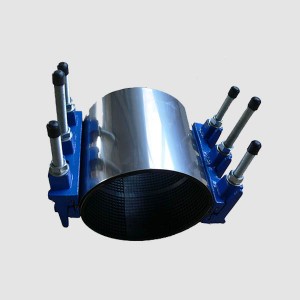

1.flexible connectionFirmness and rot- resistance

2. Need no welding

3. Without fire danger

4. Saving space

5. No limit on a pipe

6. Non-stop plugging

7. Convenient installation

Install Tips

1. Clean up the appearance of the pipe as thoroughly as possible

2. Make a reference mark on the pipe. After the installation is complete, this mark can be used to check whether the patcher is accurately covered.

3. Use water, soapy water to lubricate the pipe, reduce friction and make the seal easier to install

4. Clean and lubricate the bolts will reduce the friction so that the torque can be transmitted to the lock more easily

5. Maintain a certain pressure in the pipeline so that the water will continue to flow and prevent foreign matter or pollutants from entering the pipeline.

6. The full-circle patcher can be easily installed to the damaged part and installed easily when the piping is fully lubricated.

7. Raising the water level above the pipeline will reduce the water spray. Patcher can be installed quickly and easily in water

8. First tighten the middle bolt to prevent water spray.