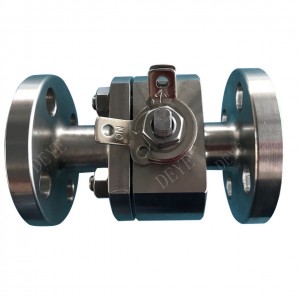

600LBS 4A DSS Trunnion Mounted ball valve

600LBS DSS Trunnion Mounted flanged ball valve

Design standard: ASME B16.34/API600

Body material: Duplex Stainless steel, DSS, 4A/5A

SAF2205/2507 /S31803/s32750

Seat: PTFE /RPTFE

Stem;F51/F53

Nominal diameter: 6″.

Pressure: 600LBS

End connection: Flanged ANSI B16.5

Face to face: ASME B16.10.

Mode of operation: lever Operated

Test and inspection: API 598.

Key Specifications / Features

Urgent grease injection device

Reliable sealing performance and small torque;

Full bore and reduced bore;

Low emission packing;

Fire safe, anti-static and anti-blowout stem design;

Product Range:

Optional Construction: 3pcs, 1pcs, 2pcs body.

Full Bore/ Reducing Bore

Floating Ball Design or Trunnion Mounted ball.

Optional Ends: flanged RTJ RF FF, NPT, BSP.

Optional seal: PTFE, RPTEF, NYLON, PEEK, Metal Seated

Optional locking device

Optional Operation: Pneumatic Actuator, Elec. Actuator. Gear+ handwheel

Available Body Material: ASTM A216WCB/LCB/CF8M/4A/5A/Alloy Steel

Available Ball : SS304, SS316, Solid Type, A105+ENP.

Pressure Range: 150LBS-1500LBS , PN10-PN250

Size Range: 1/2”-24” DN15-DN600mm

Performance:

Duplex Stainless Steel (DSS) refers to ferrite and austenite, each accounting for about 50%, and generally the stainless steel with a minimum phase content of at least 30%. In the case of low C content, Cr content is 18%~28%, Ni content is 3%~10%. Some steels also contain alloying elements such as Mo, Cu, Nb, Ti, and N.

This type of steel has the characteristics of austenitic and ferritic stainless steel. Compared with ferrite, it has higher plasticity and toughness, no room temperature brittleness, and has significantly improved intergranular corrosion resistance and welding performance, while maintaining iron. The 475°C brittleness and high thermal conductivity of plain stainless steel are characterized by super plasticity. Compared with austenitic stainless steel, the strength is high and the resistance to intergranular corrosion and chloride stress corrosion is significantly improved. Duplex stainless steel has excellent pitting corrosion resistance and is also a nickel-saving stainless steel.

Duplex code:

Duplex S331803. Super Duplex s2750. Super Duplex s32760

1A. 2A.3A. 4A, 5A.6A. 1B.1c

CE8MN. CD6MN. CD3MN.CE3MN.CD3MWCuN, CD4MCu.CD4MCuN.CD3MCuN.

F51.F53. F55. F60

Application:

widely used in crtitical ambient conditions includes Sea water, acid fluid, Bridge structure, subsea pressure pipeline, petroleum refining, chemical industry, papermaking, pharmaceutical, water conservancy, power, municipal, Steel and other fields.

Optional Construction: 3pcs, 1pcs, 2pcs body.

Full Bore/ Reducing Bore

Floating Ball Design or Trunnion Mounted ball.

Optional Ends: flanged RTJ RF FF, NPT, BSP.

Optional seal: PTFE, RPTEF, NYLON, PEEK, Metal Seated

Optional locking device

Optional Operation: Pneumatic Actuator, Elec. Actuator. Gear+ handwheel

Available Body Material: ASTM A216WCB/LCB/CF8M/4A/5A/Alloy Steel

Available Ball : SS304, SS316, Solid Type, A105+ENP.

Pressure Range: 150LBS-1500LBS , PN10-PN250

Size Range: 1/2”-24” DN15-DN600mm

Duplex Stainless Steel (DSS) refers to ferrite and austenite, each accounting for about 50%, and generally the stainless steel with a minimum phase content of at least 30%. In the case of low C content, Cr content is 18%~28%, Ni content is 3%~10%. Some steels also contain alloying elements such as Mo, Cu, Nb, Ti, and N.

This type of steel has the characteristics of austenitic and ferritic stainless steel. Compared with ferrite, it has higher plasticity and toughness, no room temperature brittleness, and has significantly improved intergranular corrosion resistance and welding performance, while maintaining iron. The 475°C brittleness and high thermal conductivity of plain stainless steel are characterized by super plasticity. Compared with austenitic stainless steel, the strength is high and the resistance to intergranular corrosion and chloride stress corrosion is significantly improved. Duplex stainless steel has excellent pitting corrosion resistance and is also a nickel-saving stainless steel.

Duplex code:

Duplex S331803. Super Duplex s2750. Super Duplex s32760

1A. 2A.3A. 4A, 5A.6A. 1B.1c

CE8MN. CD6MN. CD3MN.CE3MN.CD3MWCuN, CD4MCu.CD4MCuN.CD3MCuN.

F51.F53. F55. F60

widely used in crtitical ambient conditions includes Sea water, acid fluid, Bridge structure, subsea pressure pipeline, petroleum refining, chemical industry, papermaking, pharmaceutical, water conservancy, power, municipal, Steel and other fields.