Threaded Y strainer with drain Plug

Products Range:stainless steel ANSI NPT BSP threaded Y filter with drain Plug

Available material of the Y strainer: CF8M ,CF8,CF3M,CF3, ductile iron

Available screen: Stainless steel 304, SS316

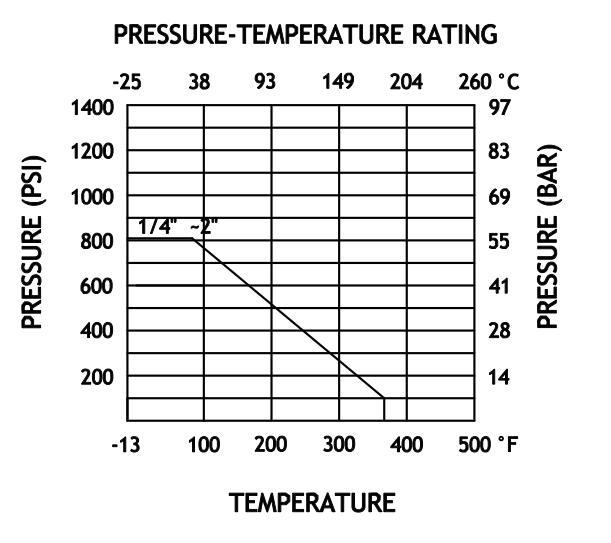

Pressure Range: 125LBS 150LBS 200WOG, 800PSI

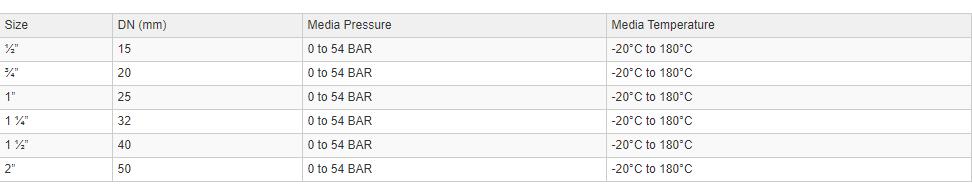

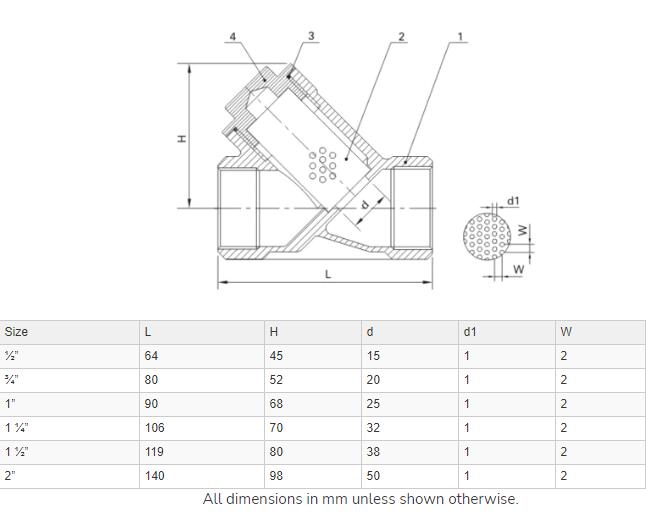

Size Range: DN15-DN50

Optional Design: Tee type, basket Type

Optional Face to Face Design: ANSI BS customized

Optional end: Thread NPT BSPT

Performance

● Y-STRAINERS furnished as standard up to sizes 2″,

● Allows for easy bolting of the cover flange.

● Tapered seats in both the body and cover flange retain screen and prevent particle bypass Construction

● All covers have NPT blowoff outlet at location C. See next page.

● Recessed seat in the cover assures accurate screen alignment.

● Bosses at the inlet and outlet flanges are provided for the gauge taps Capacity

● Generously proportioned bodies

● Open Area Ratio much greater than pipe size, ensuring low pressure drop

Application

⒈Irrigation of garden lawn and agriculture.

⒉Total water supply filtration system in the catering, textile, mining, electronics, foundry industries.

⒊Nozzles for pulp, paper, metallurgy and machinery industries are filtered with water.

⒋General circulating water filtration in food, power, mining and smelting industries.

⒌The filtration of circulating water in the cooling tower of medicine, petrochemical refining, air conditioning system or heating system.

6.Sewage ion exchange pretreatment for petrochemical, electromechanical, pharmaceutical