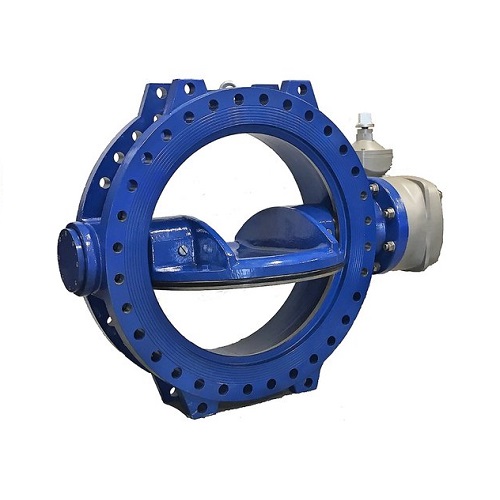

AWWA c504 Short Type Eccentric Butterfly Valve

Double Offset Butterfly valves with standard of AWWAC504, short type.

Working Rressure of 125psi 150psi 250psi

Temp –10ºC to 120ºC

Size Range: 6″-78″

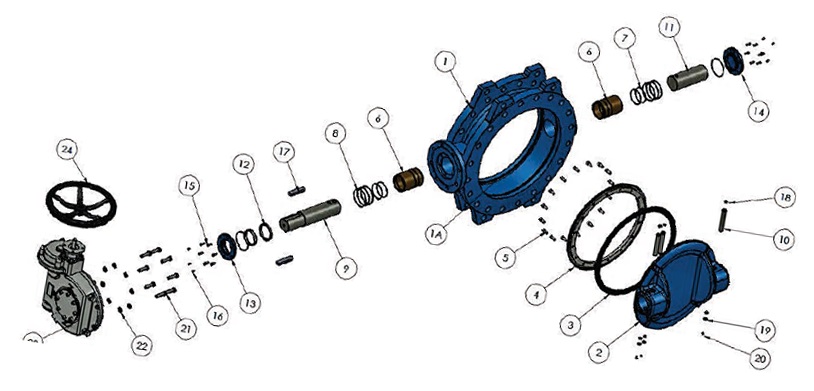

Main Part Material List and optional

| Body | A536 Gr.65-45-12, A216WCB, SS304, SS316, Duplex SS 2205/2507 | |||||

| Body Seat | SS316L Stainless steel overlay with welding, Duplex SS 2205/2207, Bronze | |||||

| Disc | A536 Gr.65-45-12, A216WCB, SS304, SS316, Duplex SS 2205/2507 | |||||

| Disc Seat Ring | A536 Gr.65-45-12, A216WCB, SS304, SS316, Duplex SS 2205/2507 | |||||

| Retaining Cover | Carbon Steel Plate / SS304/SS3116 | |||||

| Shaft | SS420, SS304, SS316, Duplex F51, F53 | |||||

Feature:

♦Double Eccentric Disc – Low Torque, Low Wear

♦Welded Body Seat Ring Stainless Steel – Reliable and

durable performance

♦Robust Buried Service Worm Gear Box, IP 67. IP68

available on request

♦Streamlined low profile Disc – Small Head loss

♦Disc to Shaft Connection – Keyway or Taper Pin

♦T profiled disc seal ring –easy adjustment

♦Multiple shaft O rings – Long life & sealing performance

♦Rapid Disc disengagement from seat

♦Self Lubricating Bronze Bearings maintenance free

♦Body & Disc Coated 250 μm FBE

♦Fasteners Stainless Steel

♦Available with a wide range of gearbox opfions includingburied duty,cap top. handwheel and actuated.

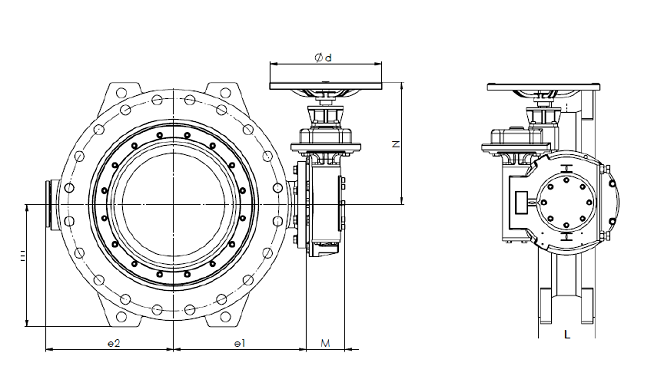

Construction and Demension List.

| NPS | e2 inch | e1 inch | M Inch | h1 inch | N Iinch | Ød inch | L |

| 6 | 6.3” | 7.09” | 3” | 5.9” | 5.66” | 9” | 5” |

| 8 | 7.68” | 8.66” | 3.2” | 7.48” | 6.1” | 9” | 6” |

| 10 | 9.25” | 9.45” | 3.2” | 8.85” | 6.1” | 9” | 8” |

| 12 | 10.63” | 11.42” | 3.2” | 9.84” | 6.22” | 9” | 8” |

| 14 | 11.54” | 12.99” | 4” | 11.2” | 12.6” | 13.1” | 8” |

| 16 | 12.99” | 14.17” | 4” | 12.6” | 12.6” | 13.1” | 8” |

| 18 | 14.17” | 14.96” | 4” | 13.38” | 12.6” | 15.7” | 8” |

| 24 | 17.91” | 18.5” | 5.47” | 16.9” | 15.47” | 15.7” | 8” |

| 36 | 26.18” | 27.17” | 6.77” | 24.2” | 20.5” | 23.62” | 12” |

| 42 | 30.51” | 31.1” | 7.9” | 27.5” | 24.8” | 23.62” | 12” |

| 48 | 35.43” | 36” | 7.9” | 31” | 26.41” | 23.62” | 15” |

| 54 | 39.37” | 40” | 7.9” | 35.2” | 27.8” | 31.49” | 15” |

| 60 | 44.09” | 46” | 9.72” | 40.55” | 29.5” | 31.49” | 18” |

| 72 | 50.39” | 51.5” | 9.72” | 40.15” | 29.5” | 31.49” | 18” |

| 78 | 55.51″ | 56″ | 10.23″ | 48.6″ | 43″ | 31.49″ | 24″ |

Avaiable Standard: AWWAC504, API609, BS5155

Avaiable Face to Face Length: AWWAC504 short /longtype, ISO5755 /EN558 Series 13/14

Size Range: 6″-78″ for AWWA standard, DN100-DN2200

Pressure Range; 125psi 150psi 225psi 250psi PN6 PN10 PN16 PN25

Material Avaiable: Ductile Iron, Carbon Steel, Stainless Steel, Duplex Stainlesss Steel

Replaceable Seat Ring: EPDM, NBR, PTFE, VITON

Body Welded Ring: SS304, SS316, Duplex SS, Bronze

UV double Eccentric Butterfly valves with double offset design occurs from the centerline of the disc rotation being horizontally and vertically offset from the stainless steel body seat. Unlike traditional concentric AWWA butterfly valves, the double eccentric design offers a “non-rubbing”resilient seat that releases compression after only a few degrees of opening, which results in a longer lifespan and provides low operating torques. Each valve is equipped with a dual shaft design giving it inherently high flow characterizes over a one piece shaft. This results in considerable savings to the owner by lowering pumping and energy costs over the lifespan of the valve.Importantly, if the resilient seat ever needed adjustment or replacement, it can be achievedwith common tools in the field compared to epoxy filled seats that require special equipment orvulcanized/bonded seats that cannot be field adjusted or replaced.

Water Treatment Plant, Drinkg Water Supply system, Municipal water projects, Pumping construcitons, buried undergroud big pipeline