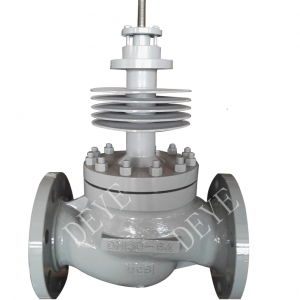

A105N Straight regulation Control valve (C-PR-1500-4)

Quick Details::High pressure 1500LBS straight globe control regulation valve.

Straight globe control valves with 1500LBS

Body:Straight-through, Forged globe valve

Material: A105N

Nominal size, 4’’

Pressure rating: ANSI 1500LBS

End connection; Flange RF ANSI B 16.5

Extension bonnet Type1(-45 to -17°C and 230 to 566°C)

Gland type: Bolted Gland

Packing: V shaped PTFE

Gasket material: Stainless steel SUS304,

Valve plug: Contoured type plug

Product Range:

Body Type Straight-through, Angle Type.

Nominal size 1’’, 1-1/2’’, 2’’, 3’’, 4’’

Pressure rating • ANSI Class 900, 1500, 2500 •

Flanged End: RF, RJ According to ANSI B16.5, JIS B2201, JPI-7S •

Welded End: SW(1 to 3 inches),/BW (3 inches)

Material A216 WCB, A217 WC6, A217 C5, A351 CF8, A351 CF8M, A351 CF3M, A351 CF3.

Pain bonnet (-5 to 230°C)

Extension bonnet Type1 (230 to 566°C)

Extension bonnet Type

Cryogenic Gland type

Bolted Gland Packing/grease graphite packing and others.

Trim Valve plug Single-seated, Contoured type

Flow characteristics: Equal percentage(%C), Linear (LC).

Actuator Type: Single-acting actuator, Spring piston actuator, Double acting actuator

Diaphragm material: Cloth embedded nylon and ethylene propylene rubber

Spring range: (0.2 to 1.0 kgf/cm2) • (0.4 to 2.0 kgf/cm2) • (0.8 to 2.4 kgf/cm2)

Supply pressure 0.14, 0.16, 0.28, 0.4, 0.5 Mpa

Air connection Rc1/4 or 1/4NPT internal thread.

Ambient temperature -30 to 70℃

Performance:

In the automatic adjustment system of the production process, the adjustment valve is an important and indispensable link. It is called the “hands and feet” of the production process automation and is one of the terminal control elements of the automatic control system.

The flow path of the regulating valve is simple and the resistance is small, and it is generally suitable for forward use (installation). However, in the case of high pressure drop, the regulating valve is used in reverse to improve the unbalanced force and reduce the damage to the valve core. At the same time, it is also conducive to the flow of the medium and avoids the coking and clogging of the regulating valve. When the regulating valve is used in the reverse direction, the opening of the small opening for a long period of time should be avoided, in order to prevent strong vibration and damage to the valve core. Especially in the trial production stage of chemical plants, due to the low load during trial production and the design process conditions cannot meet the requirements quickly, the reverse use of the control valve should avoid the opening condition of the small opening for a long time as far as possible to prevent the control valve damage.

The regulating valve is composed of an actuator and a valve. From the hydraulic point of view, the regulating valve is a throttling element whose local resistance can be changed. The regulating valve changes the resistance coefficient by changing the stroke according to the input signal, so as to achieve the purpose of regulating the flow rate.

Application:

The regulating valve is suitable for air, water, steam, various corrosive media, mud, oil and other media

Body Type Straight-through, Angle Type.

Nominal size 1’’, 1-1/2’’, 2’’, 3’’, 4’’

Pressure rating • ANSI Class 900, 1500, 2500 •

Flanged End: RF, RJ According to ANSI B16.5, JIS B2201, JPI-7S •

Welded End: SW(1 to 3 inches),/BW (3 inches)

Material A216 WCB, A217 WC6, A217 C5, A351 CF8, A351 CF8M, A351 CF3M, A351 CF3.

Pain bonnet (-5 to 230°C)

Extension bonnet Type1 (230 to 566°C)

Extension bonnet Type

Cryogenic Gland type

Bolted Gland Packing/grease graphite packing and others.

Trim Valve plug Single-seated, Contoured type

Flow characteristics: Equal percentage(%C), Linear (LC).

Actuator Type: Single-acting actuator, Spring piston actuator, Double acting actuator

Diaphragm material: Cloth embedded nylon and ethylene propylene rubber

Spring range: (0.2 to 1.0 kgf/cm2) • (0.4 to 2.0 kgf/cm2) • (0.8 to 2.4 kgf/cm2)

Supply pressure 0.14, 0.16, 0.28, 0.4, 0.5 Mpa

Air connection Rc1/4 or 1/4NPT internal thread.

Ambient temperature -30 to 70℃

In the automatic adjustment system of the production process, the adjustment valve is an important and indispensable link. It is called the “hands and feet” of the production process automation and is one of the terminal control elements of the automatic control system.

The flow path of the regulating valve is simple and the resistance is small, and it is generally suitable for forward use (installation). However, in the case of high pressure drop, the regulating valve is used in reverse to improve the unbalanced force and reduce the damage to the valve core. At the same time, it is also conducive to the flow of the medium and avoids the coking and clogging of the regulating valve. When the regulating valve is used in the reverse direction, the opening of the small opening for a long period of time should be avoided, in order to prevent strong vibration and damage to the valve core. Especially in the trial production stage of chemical plants, due to the low load during trial production and the design process conditions cannot meet the requirements quickly, the reverse use of the control valve should avoid the opening condition of the small opening for a long time as far as possible to prevent the control valve damage.

The regulating valve is composed of an actuator and a valve. From the hydraulic point of view, the regulating valve is a throttling element whose local resistance can be changed. The regulating valve changes the resistance coefficient by changing the stroke according to the input signal, so as to achieve the purpose of regulating the flow rate.

The regulating valve is suitable for air, water, steam, various corrosive media, mud, oil and other media